Direct-to-Movie (DTF) printing has emerged as a sport-changing expertise within the textile and apparel trade, providing a versatile and efficient different to conventional printing strategies. This report delves into the mechanics, benefits, applications, and future prospects of DTF printers.

What is DTF Printing?

DTF printing is a process that entails printing designs onto a particular movie, which is then transferred onto fabrics utilizing heat and stress. The method begins with the creation of a digital design, which is printed onto a switch movie utilizing specialised DTF ink. The printed film is coated with a powder adhesive, which is then cured using heat. Finally, the film is positioned on the specified fabric and heat pressed, allowing the ink to bond with the material.

Key Components of DTF Printers

DTF printers consist of a number of key parts that work in harmony to supply excessive-quality read more prints. These include:

- Printer: DTF printers make the most of inkjet know-how, typically geared up with multiple print heads to make sure excessive-pace printing and vibrant colors.

- Inks: DTF inks are specifically formulated to adhere to the movie and bond effectively with varied fabrics. These inks usually encompass water-based pigments that produce bright and lengthy-lasting colors.

- Transfer Movie: This is a coated movie that acts as the medium for the printed design. The movie is designed to withstand heat and pressure during the switch process.

- Adhesive Powder: After printing, a powdered adhesive is utilized to the wet ink on the film. This powder is essential as it helps the ink adhere to the fabric during the heat switch process.

- Heat Press: A heat press is used to use the mandatory heat and pressure to transfer the design from the movie to the fabric. The temperature and duration of this process can range depending on the fabric being printed on.

Advantages of DTF Printing

DTF printing provides numerous benefits over traditional printing strategies, making it a sexy choice for companies and individuals alike:

- Versatility: DTF printing can be used on a large number of fabrics, including cotton, polyester, and blends. This versatility allows for a broader vary of applications, from t-shirts to bags and house textiles.

- Vibrant Colours: The use of high-high quality inks ensures that the prints produced are vibrant and true to the unique design. DTF printing can obtain a wide coloration gamut, making it appropriate for intricate designs and detailed graphics.

- Sturdiness: DTF prints are recognized for their durability and resistance to cracking, fading, and peeling. This makes them superb for objects that undergo regular washing or wear, resembling clothes and equipment.

- Value-Efficient: DTF printing eliminates the necessity for screens and plates, reducing setup prices and making it economically viable for small batches. This is especially useful for customized orders and small companies.

- Ease of Use: The DTF printing course of is comparatively easy, requiring minimal training for operators. The ability to print immediately from digital files streamlines production and reduces the time wanted to get merchandise to market.

Functions of DTF Printing

DTF printing has found applications across varied sectors, together with:

- Apparel: Customized t-shirts, hoodies, and sportswear are widespread purposes, permitting for customized designs and branding.

- Promotional Products: DTF printing is right for creating promotional objects similar to baggage, caps, and other merchandise that may be custom-made for events and advertising and marketing campaigns.

- Residence Decor: The flexibility to print on various fabrics opens up alternatives in dwelling textiles, including curtains, pillowcases, and tablecloths.

- Vogue Industry: Designers are increasingly adopting DTF printing for restricted edition collections and unique fabric prints, permitting for fast prototyping and manufacturing.

Future Prospects

As expertise continues to evolve, the way forward for DTF printing seems promising. Innovations in ink formulations, printer capabilities, and switch movies are expected to reinforce print quality and develop the vary of functions. Moreover, as sustainability turns into a priority in the textile trade, DTF printing affords an eco-friendlier various to traditional methods, with water-based mostly inks and lowered waste.

Conclusion

DTF printers characterize a big development in the textile printing landscape, combining versatility, price-effectiveness, and excessive-high quality output. As extra businesses and individuals acknowledge the advantages of DTF printing, it's likely to grow to be a standard choice for custom apparel and textiles. With ongoing developments in know-how and rising demand for personalised merchandise, DTF printing is poised to play a crucial role in the future of the printing business.

Spencer Elden Then & Now!

Spencer Elden Then & Now! Patrick Renna Then & Now!

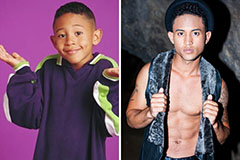

Patrick Renna Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Ashley Johnson Then & Now!

Ashley Johnson Then & Now! Shane West Then & Now!

Shane West Then & Now!